Transforming Traditional Manufacturing: Intermark’s Digital Evolution.

Politecnico di Milano, Master’s Thesis in Product Service System Design.

This project delves into the intersection of design, technology, and operations, focusing on Intermark—a family-owned paper converting factory in Saudi Arabia.

My role encompassed in-depth research, strategic analysis, and design proposal development to guide the company through its Industry 4.0 journey.

About.

Intermark, founded in 1995, specialises in adhesive labels, thermal rolls, and packaging materials. Despite its success, the company faced significant challenges:

-Heavy reliance on manual workflows.

-Communication delays across departments.

-Limited customer engagement tools.

-Outdated technology that hindered scalability and responsiveness.

The goal was to redefine Intermark’s operations and customer experience by introducing a comprehensive, digitally integrated system.

Key Objectives.

1- Streamline Operations: Introduce automation to eliminate repetitive manual tasks and enhance production efficiency.

2- Enhance Customer Engagement: Design a customer-friendly e-commerce platform with real-time updates and customisation options.

3- Foster Collaboration: Develop an integrated communication system for seamless departmental interactions.

4- Prepare for Scalability: Create a framework that supports growth and adapts to evolving industry needs.

Research & Methodology.

Primary Research.

Interviews: Conducted 15+ semi-structured interviews with senior managers and employees to understand their operational workflows, customer challenges, and digital readiness.

Field Observations: Spent 5+ days shadowing key departments (production, logistics, sales) to uncover pain points in task execution, order processing, and communication.

Research & Methodology.

Service Design Tools.

Customer Personas: Developed profiles to highlight diverse needs, such as first-time customers and returning corporate clients.

Sarah Ahmed is a 32-year-old small business owner launching her first restaurant, focused on eco-friendly and high-quality dining experiences.

As a first-time customer of Intermark, she needs customised packaging materials for her restaurant’s takeout and delivery services. Sarah values efficiency and transparency but is unfamiliar with Intermark’s processes. She discovered the company through Instagram but found it challenging to navigate the limited information available online.

Sarah hopes for a seamless experience where she can easily place orders, track progress, and receive clear communication throughout the process.

REAL-LIFE PERSONA.

Journey Mapping: Mapped customer experience to identify friction points and opportunities for improvement.

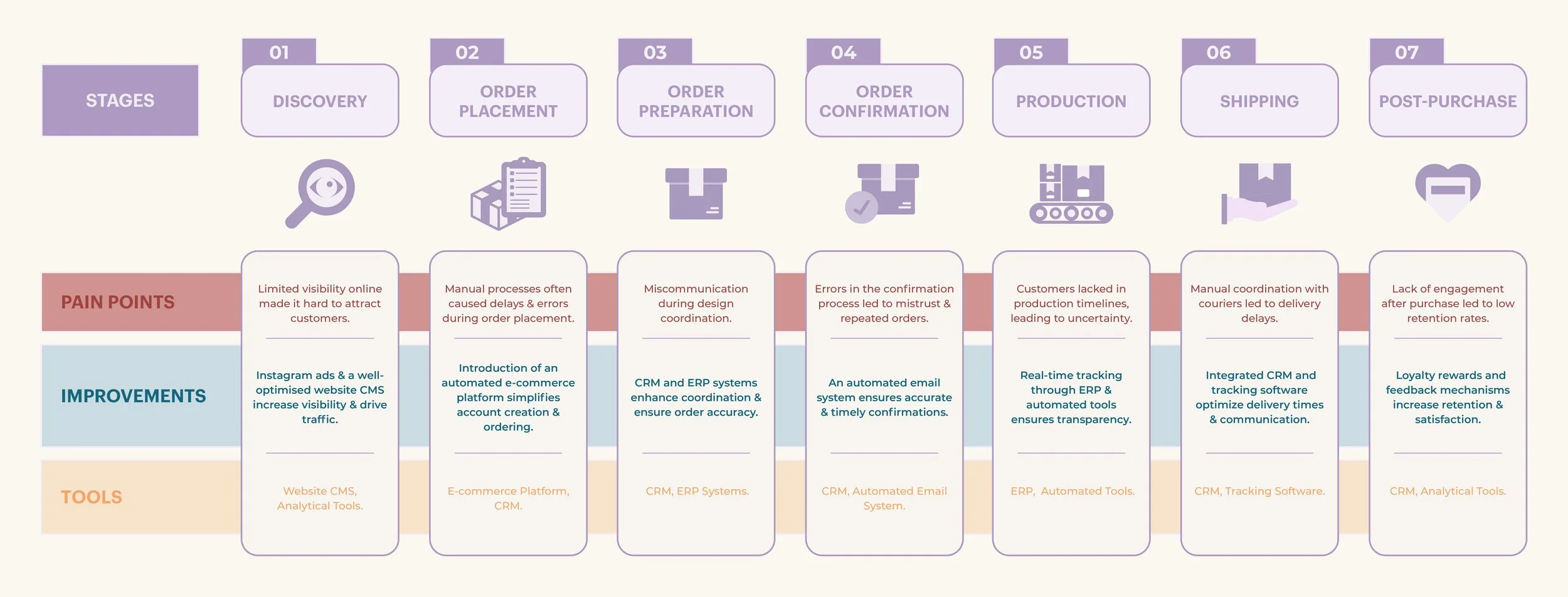

Current Customer Journey Experience.

System Blueprinting: Used system blueprinting to understand the pain points of the company's internal and external processing, improving the connection between operations and customer-facing services.

Current Service Process: Internal and External Challenges.

Research & Methodology.

Problem Identification.

1- Operational Inefficiencies.

Inefficiencies due to reliance on manual work, outdated software, and manual inventory checks.

2- Customer Experience Gaps.

Lack of online visibility and real-time order tracking.

3- Employee Challenges.

Frustration from repetitive tasks and limited digital tools.

The dual-platform solution revolutionises both employee and customer experiences by automating workflows to reduce manual processes and improve efficiency. It enhances communication by fostering better coordination across departments and touchpoints, creating a more seamless operational environment. Additionally, the platform provides real-time data, enabling informed decision-making and proactive management to address challenges effectively and optimise outcomes.

The Digital Backbone: Our New Platform.

Proposed Solution.

This system integrates internal operations with external customer engagement, delivering a seamless, efficient environment that drives both operational excellence and customer satisfaction.

A Unified Solution: How the Platform Connects It All.

Proposed Solution.

Customer Experience

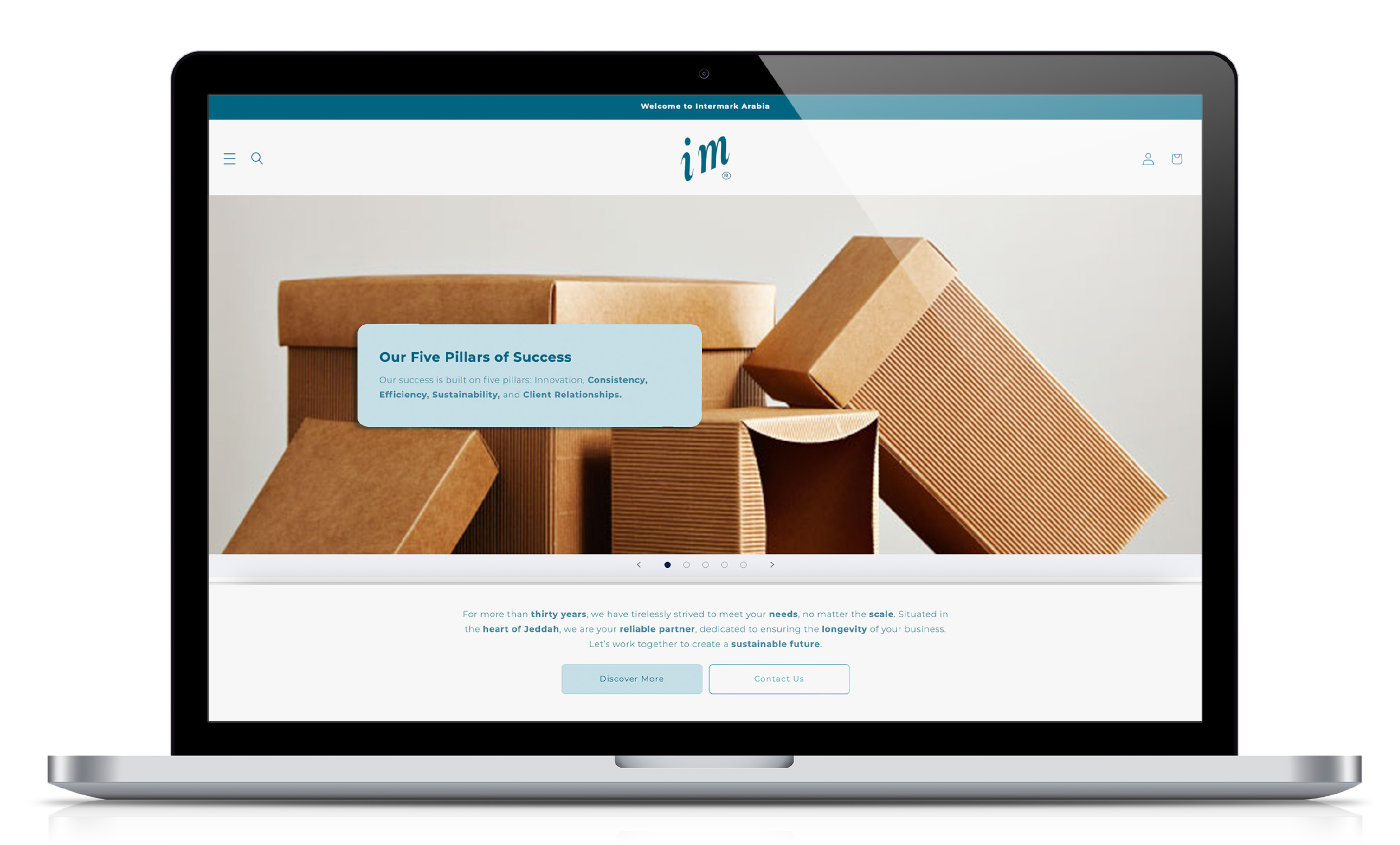

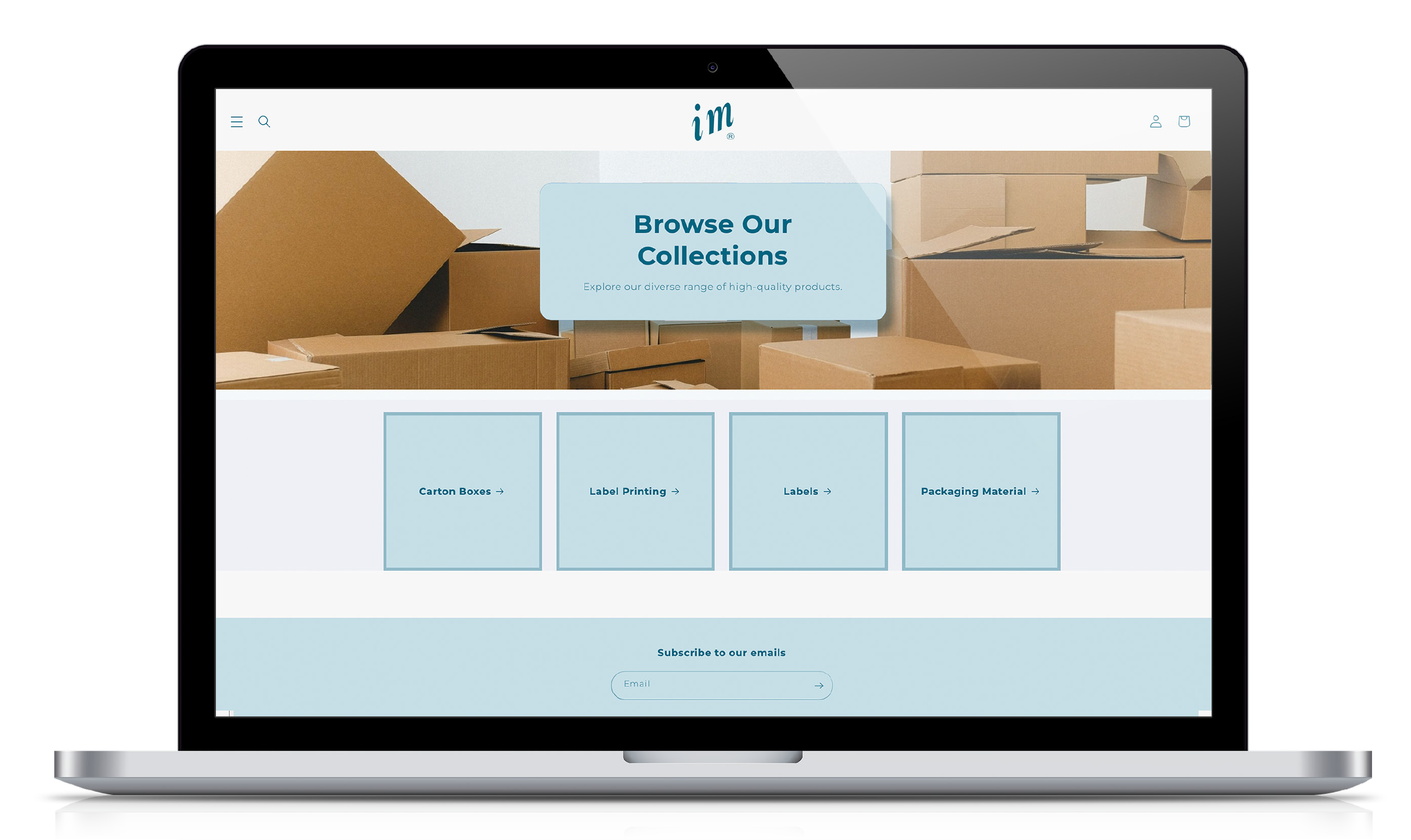

The platform integrates e-commerce functionality, ensuring a seamless journey from order placement to delivery tracking. Real-time updates and a personalised portal enhance transparency, reduce frustration, and foster customer trust.

E-Commerce Functionality.

Customer Portal — Dashboard.

Customer Portal — New Order.

Customer Portal — Track Order.

Customer Portal — Order History.

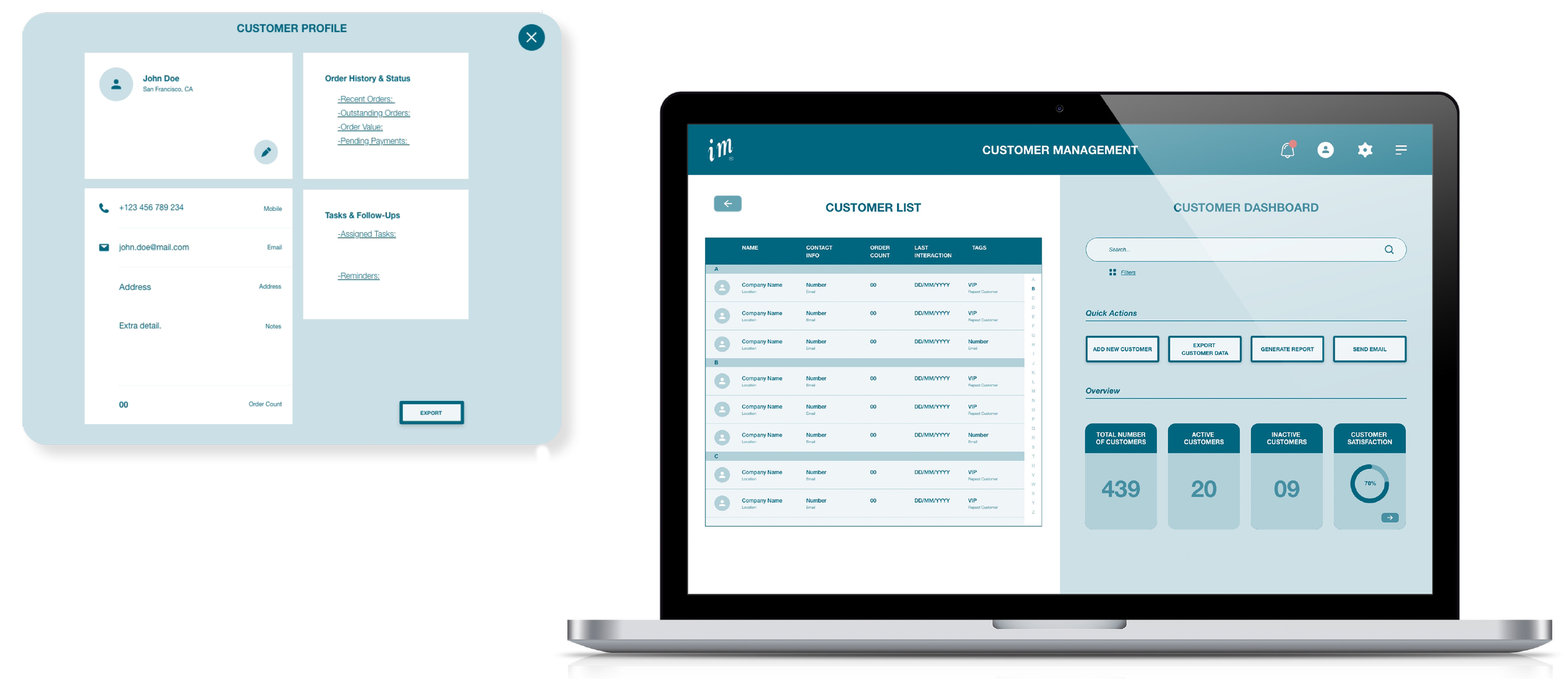

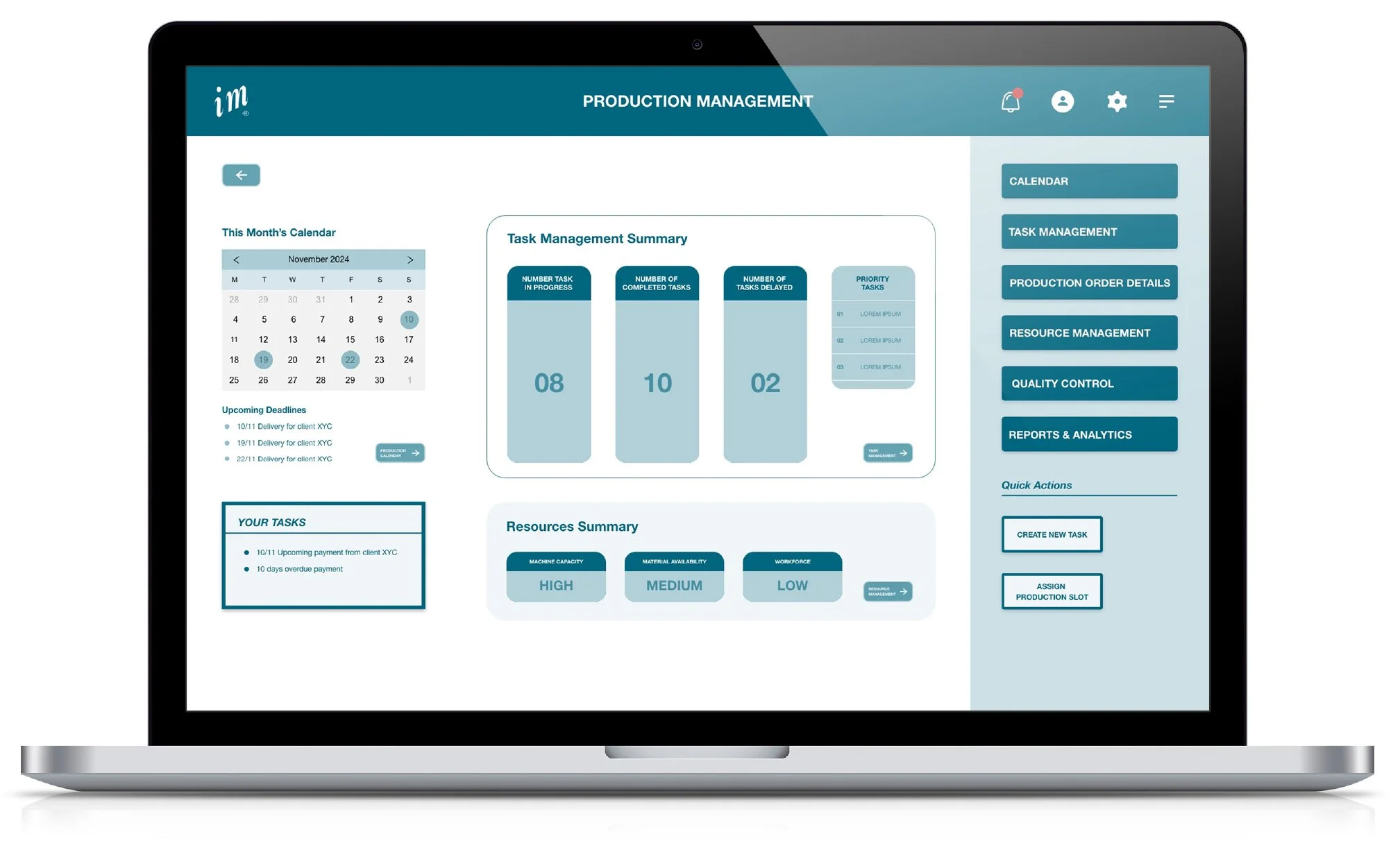

Employee Efficiency & Management Control.

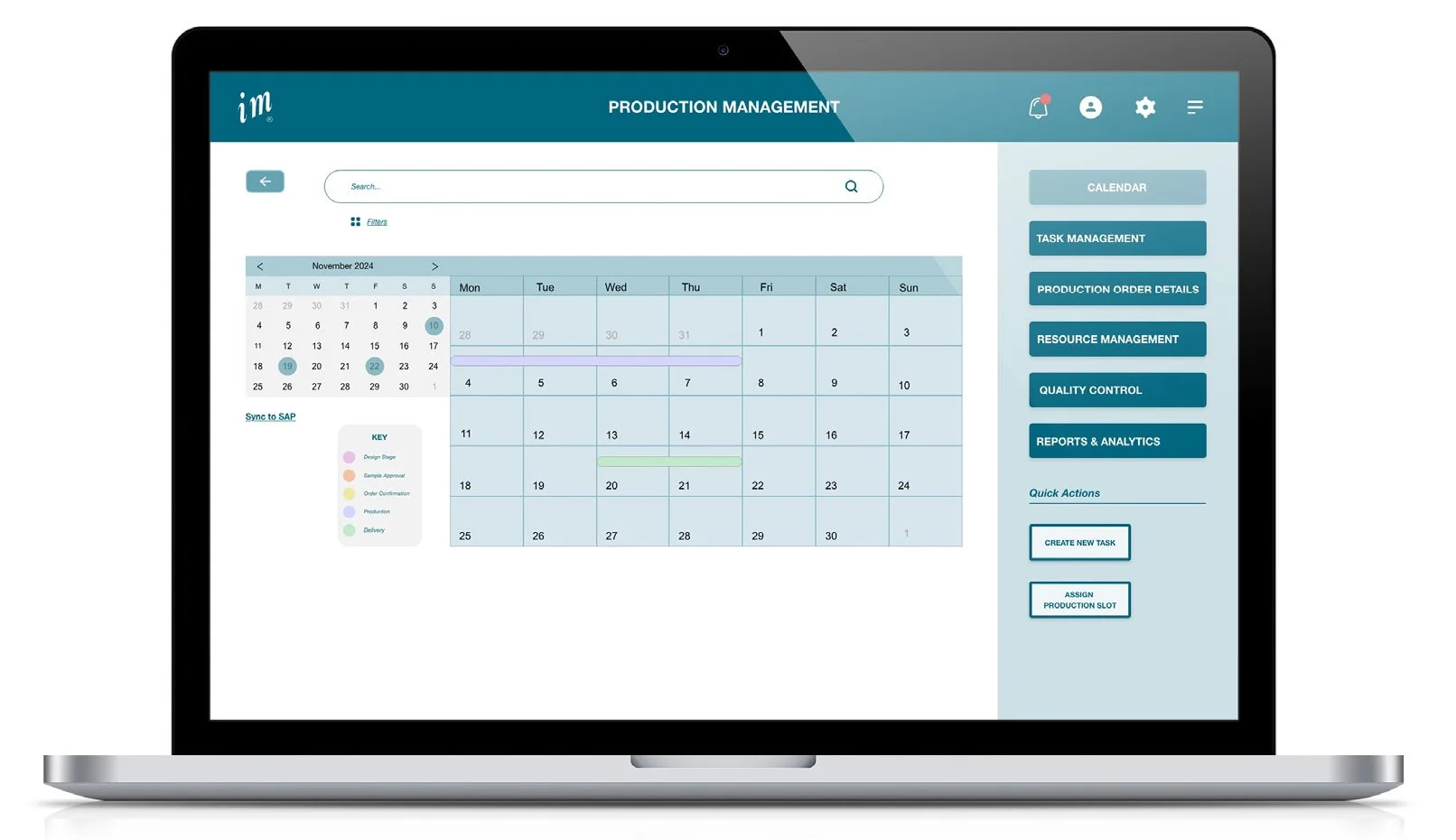

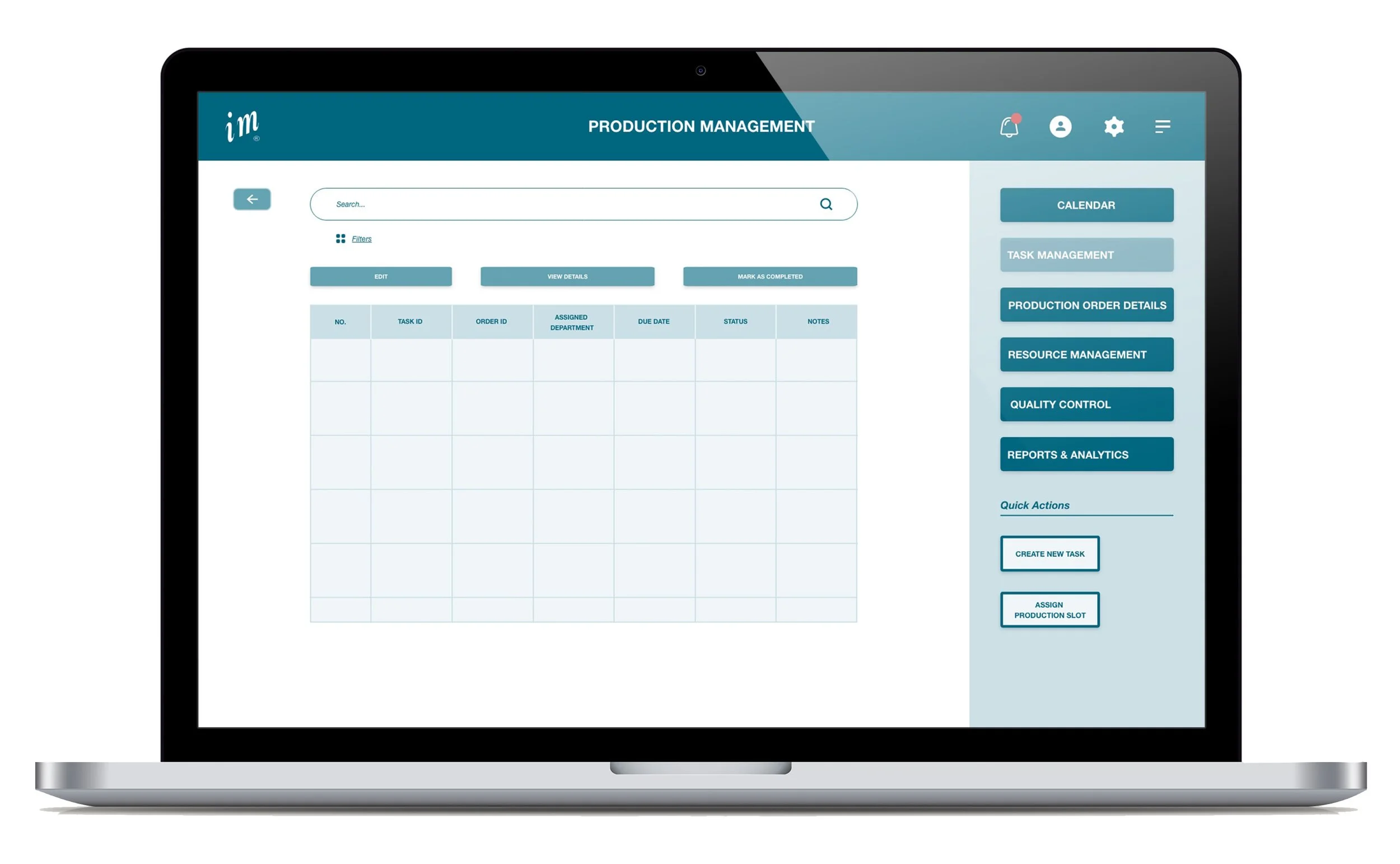

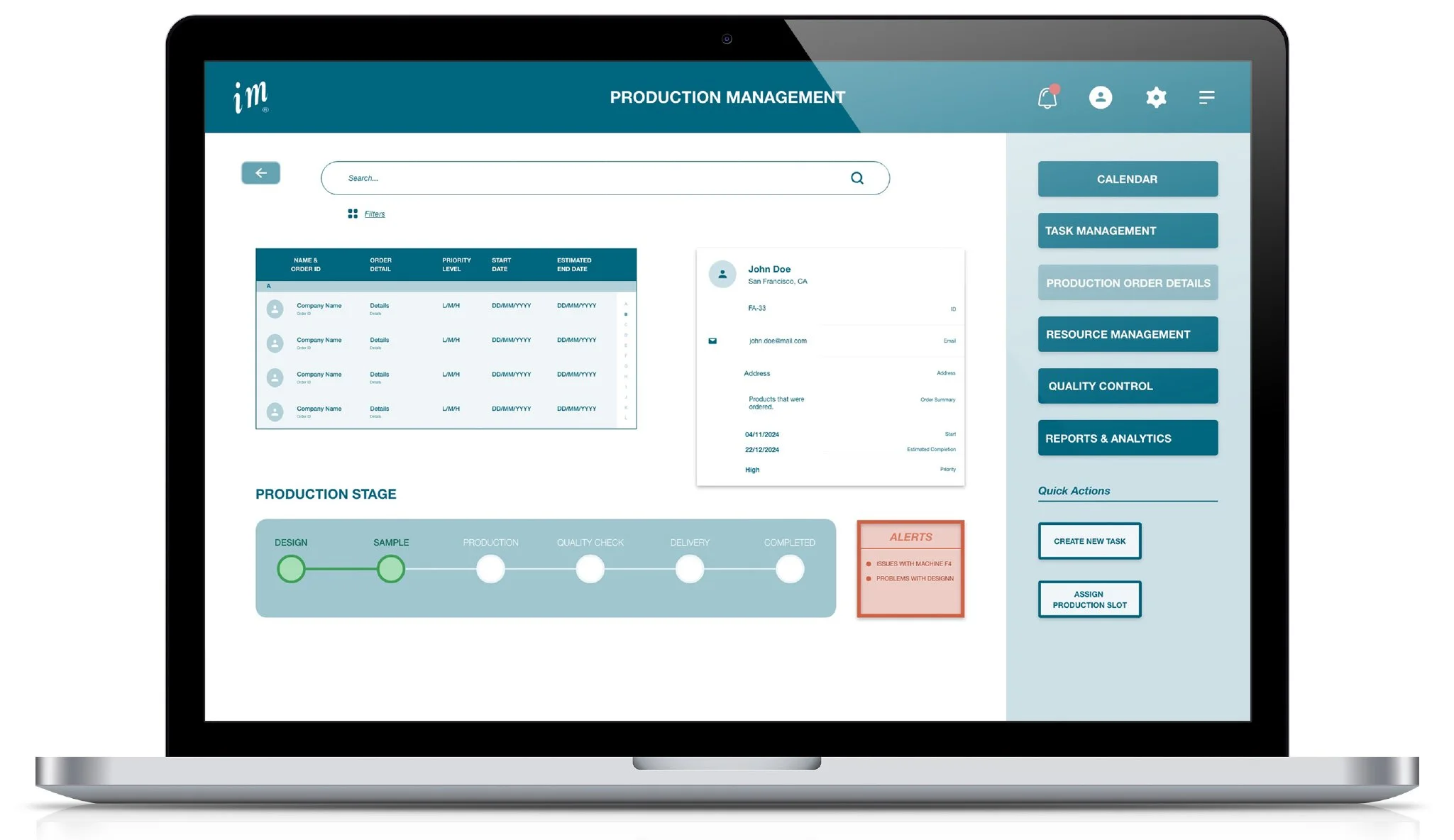

Task automation and real-time tools streamline workflows, enhance team collaboration, and accelerate production and delivery timelines. Simultaneously, real-time dashboards provide comprehensive visibility into resource allocation, performance metrics, and customer satisfaction, enabling informed decision-making and efficient operations management.

Employee Portal — Login Dashboard.

Employee Portal — Dashboard.

Employee Portal — Customer Management.

Employee Portal — Order Management.

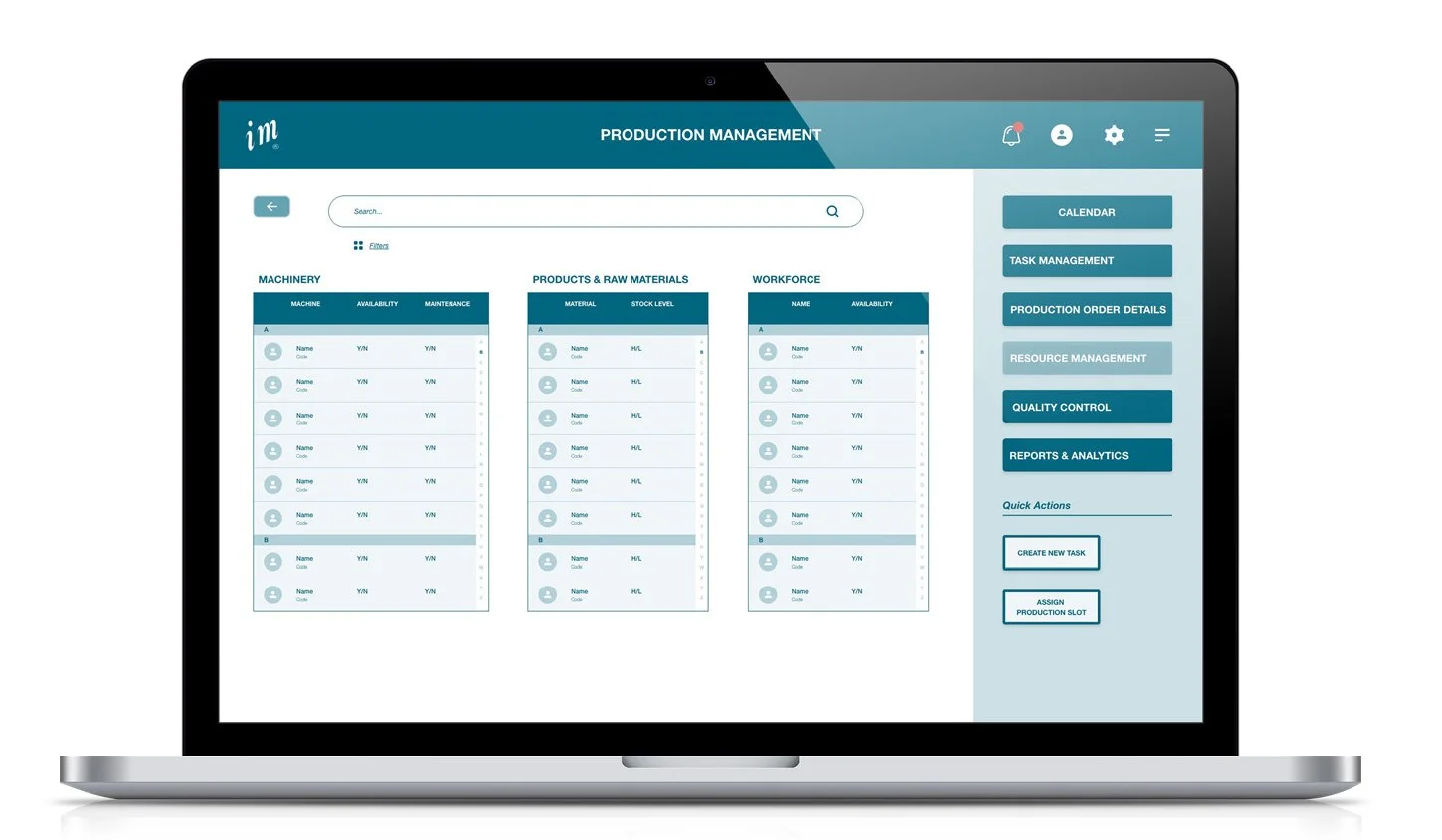

Employee Portal — Production Management Dashboard.

Employee Portal — Production Management Calendar.

Employee Portal — Production Management Task Management.

Employee Portal — Production Management Order Details.

Employee Portal — Production Management Resource Management.

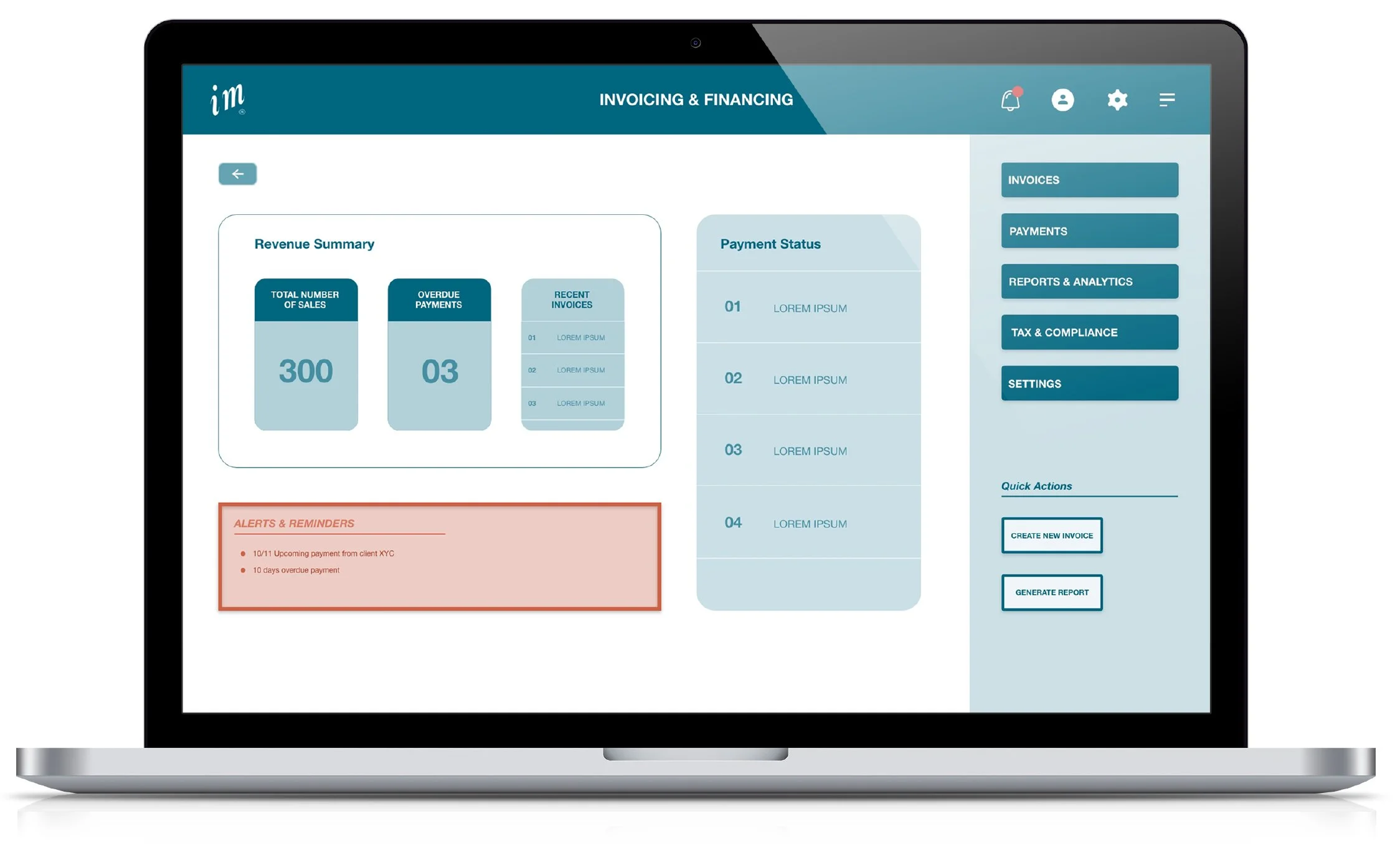

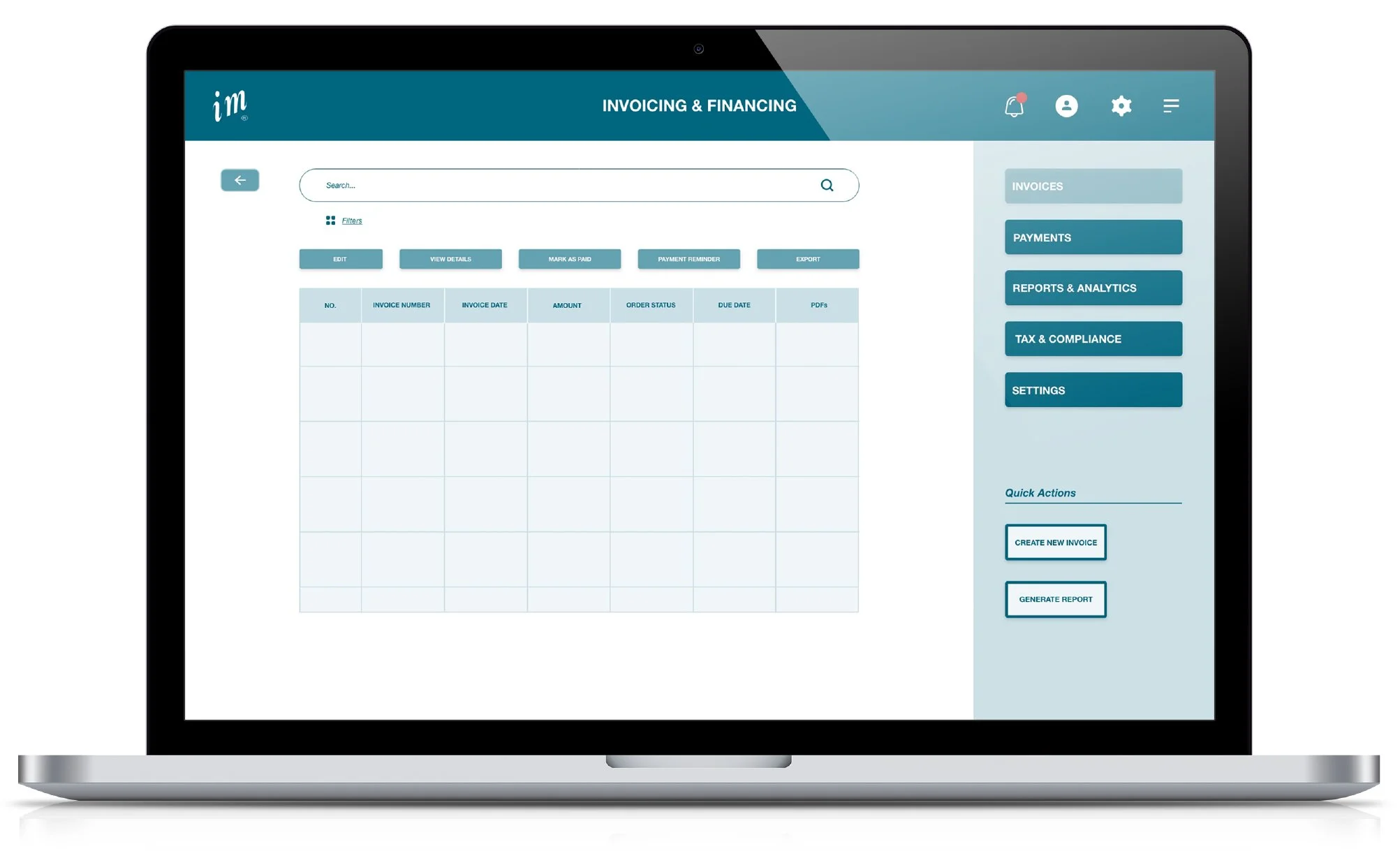

Employee Portal — Invoicing & Financing.

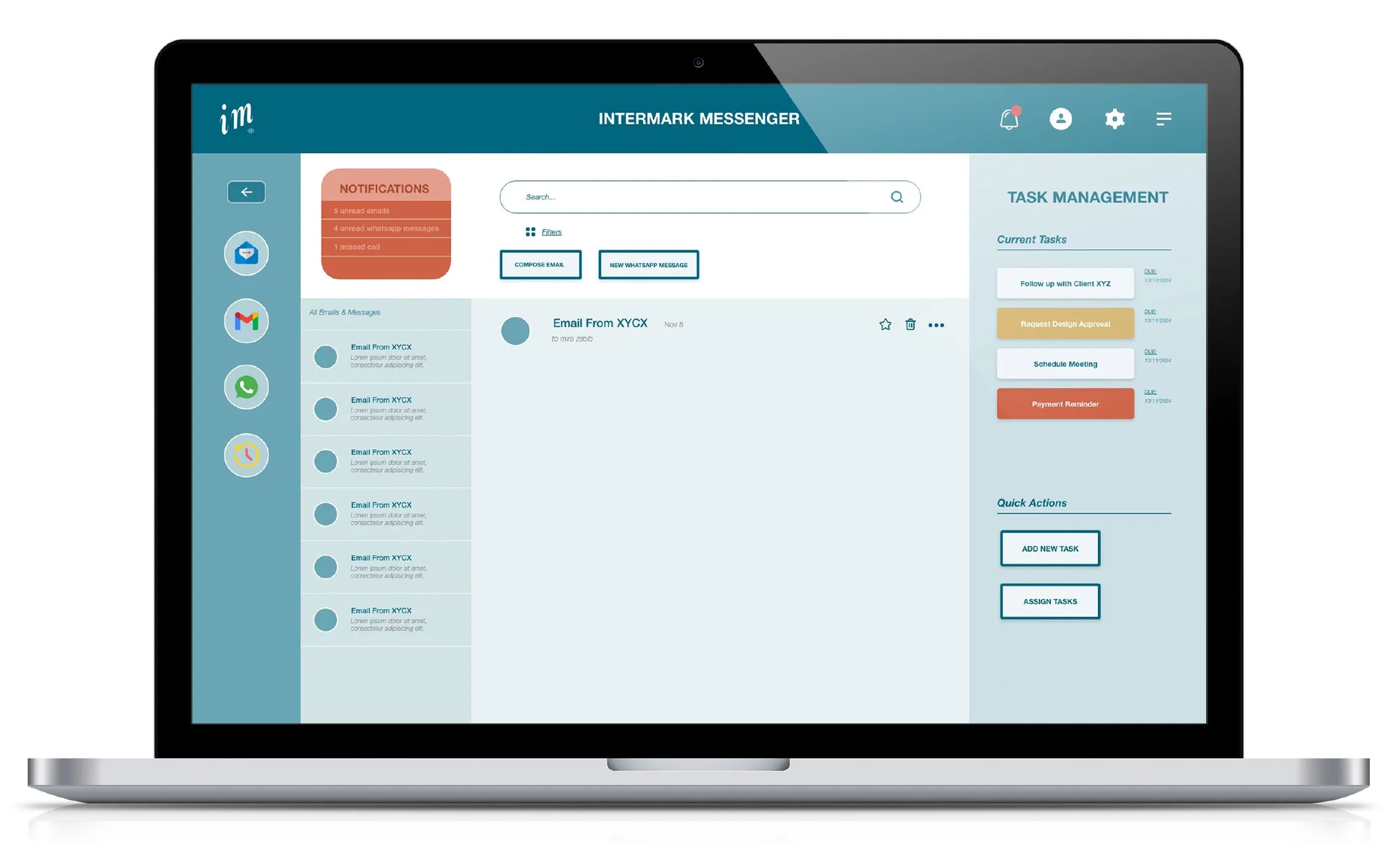

Employee Portal — Intermark Messenger.

The digital backbone bridges operational gaps and enhances user experiences, positioning Intermark as a future-ready, customer-centric industry leader while fostering sustainable growth and delivering a cohesive, satisfying experience for all stakeholders.

With this proposed transformation, Intermark could redefine how it engages with customers and supports its employees.

By implementing a streamlined customer journey, enhancing employee workflows, introducing innovative service offerings, and adopting a modernised organisational structure, the company would be well-positioned to create a more efficient and satisfying experience for all stakeholders.

Enhanced System Overview & Service Mapping.

Proposed Solution.

The reimagined customer journey addresses inefficiencies, communication gaps, and engagement challenges by integrating a dual-platform system. This solution streamlines interactions, enhances transparency, and fosters long-term loyalty for both new and recurring customers.

For New Customers. The journey begins with discovery through targeted campaigns leading to an optimised website. Customers can easily explore products, create accounts, and place orders with minimal friction. Key features include real-time order tracking, personalised updates, and loyalty rewards to encourage feedback and repeat purchases.

For Recurring Customers. The focus shifts to building loyalty and simplifying reorders with streamlined processes, personalised recommendations, and transparent production and shipping updates. Loyalty incentives further strengthen customer retention and lifetime value.

A Seamless Customer Journey.

Stages of Improvement: From Pain Points to Solutions.

Key touchpoints and tools work together to create a seamless customer experience. An enhanced e-commerce platform enables effortless product exploration and ordering, while CRM systems and automated email tools ensure personalised and timely communication. Real-time tracking provides transparency throughout the production and delivery process, keeping customers informed and engaged at every stage.

Impact and Collaboration. The solution drives measurable outcomes, such as increased conversion rates, repeat purchases, and improved customer satisfaction. Collaboration across marketing, sales, logistics, and customer service ensures smooth implementation, supported by analytics tools for continuous improvement.

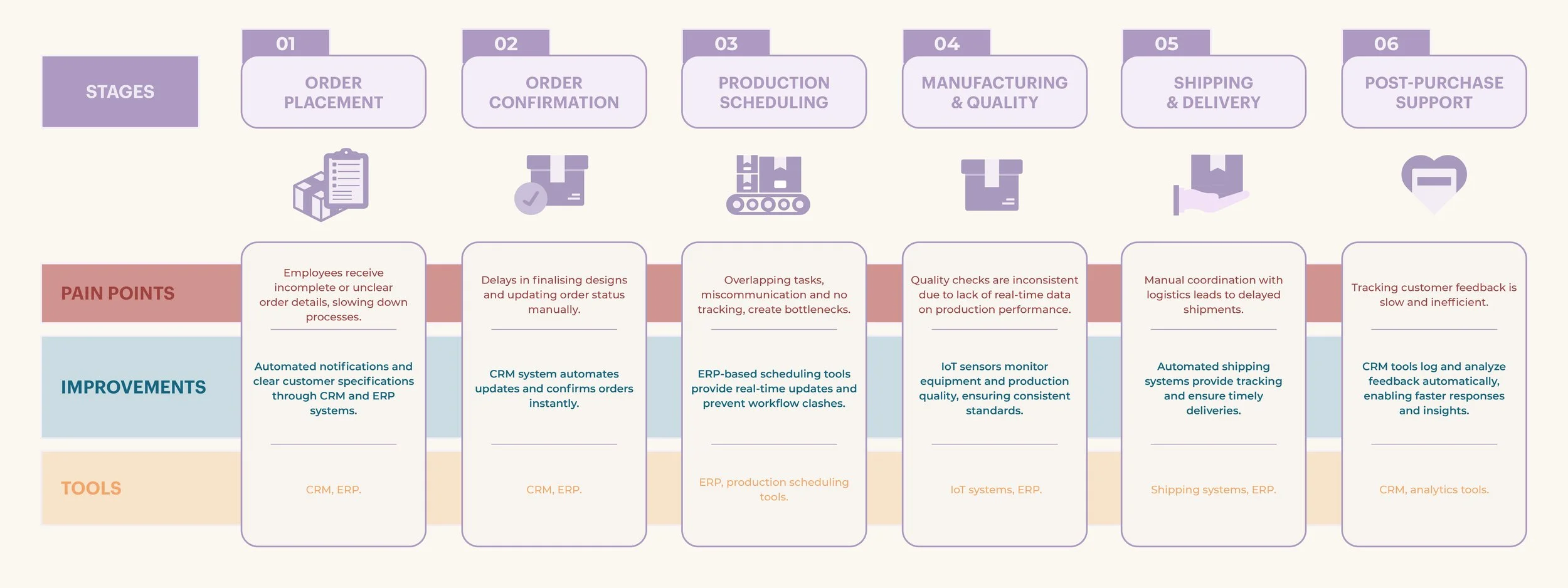

The redesigned employee journey empowers manufacturing and production staff with tools and processes to streamline workflows and boost productivity. The dual-platform system facilitates efficient order management, quality assurance, and communication for seamless operations.

The Employee Journey: From Order to Delivery. The journey begins when employees receive notifications for new orders, enabling them to review the details and ensure alignment with production capabilities. During the design phase, they update specifications to guarantee feasibility and accuracy before finalising designs. Once designs are confirmed, tasks are allocated, and production is scheduled through optimised workflows that minimise delays and enhance efficiency.

As production begins, employees closely monitor progress in real time, conducting quality checks to ensure the output consistently meets high standards. After manufacturing is complete, they coordinate with logistics teams to ensure timely delivery. Post-delivery, employees track customer feedback, using these insights to refine future processes and continuously improve the system.

The Redefined Employee Experience.

Operational Transformation: Stages, Pain Points Solutions.

Impact Metrics and KPIs. This process is designed to enhance key performance metrics, including faster acknowledgment of orders, improved design accuracy, more efficient workflows, and consistent product quality.

By reducing friction and enabling real-time updates, the system empowers employees to focus on delivering exceptional results, fostering collaboration and boosting overall productivity

The Enhanced Management Experience.

Upper management plays a key role in overseeing the service delivery process with the support of the dual-platform system. From the moment orders are received to ensuring customer satisfaction, their focus is on allocating resources effectively, making thoughtful decisions, and maintaining smooth operations to achieve business goals.

The Strategic Management Experience. The Management Journey Map showcases the vital role of upper management in steering the service delivery process through a dual-platform system. It includes key phases such as reviewing customer orders to align with strategic goals, allocating resources effectively, managing budgets to ensure cost-efficiency, monitoring production for quality and performance, optimising logistics for timely deliveries, and refining processes based on customer feedback.

Through close collaboration with employees, management fosters seamless operations, enhancing efficiency, accuracy, and customer satisfaction. Together, they overcome challenges, simplify workflows, and drive organisational success.

Operational Transformation: Stages, Pain Points Solutions.

By integrating analytics tools, ERP systems, and CRM platforms, management tracks performance, ensures alignment across departments, and drives operational success. Regular team meetings and data-driven insights foster strategic decision-making and continuous improvement.

The Management Journey Map works alongside the Employee Journey Map, illustrating how both roles come together to create a smoother, more efficient process. By working in sync, these journeys help resolve challenges, simplify operations, and improve both team performance and customer satisfaction.

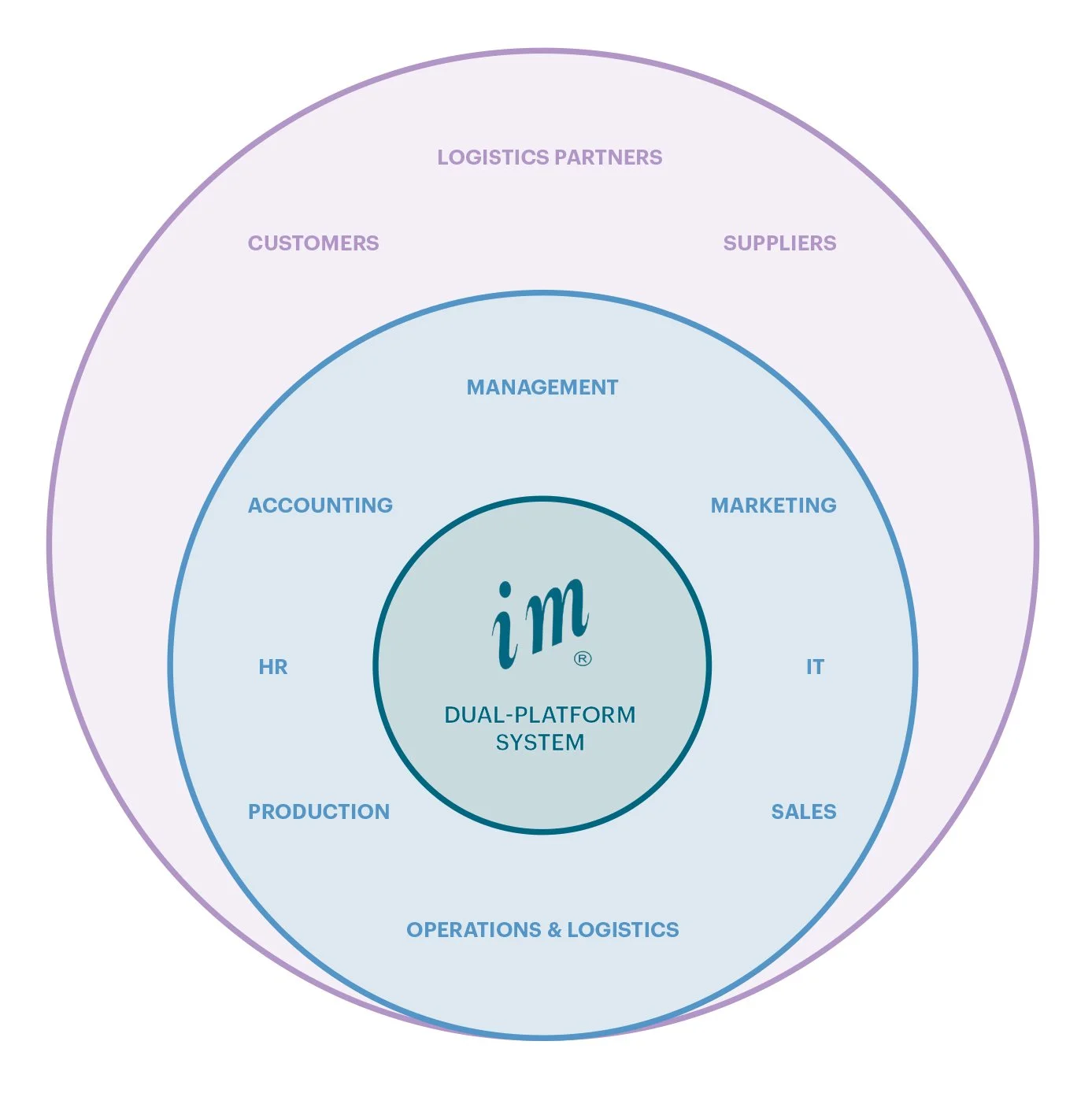

Intermark’s Connected Business Ecosystem.

The Ecosystem Map provides a strategic overview of Intermark’s interconnected internal functions and external stakeholders, demonstrating how digital transformation enhances collaboration, efficiency, and agility.

At the core of the map are Intermark’s internal operations: Design Services, Manufacturing & Production, Supply Chain & Logistics, Sales & Marketing, and Customer Support. These departments form the backbone of the company’s processes, leveraging advanced digital tools such as CRM systems, ERP platforms, and IoT sensors to improve resource allocation, streamline workflows, and enable real-time decision-making.

Surrounding this core are external stakeholders—Customers, Suppliers, and Logistics Partners—who play a vital role in the ecosystem. Digital solutions foster seamless collaboration, offering personalized customer experiences through online portals and support systems, real-time inventory management for suppliers, and optimised logistics tracking for timely and cost-effective deliveries.

This integrated ecosystem ensures smooth communication and data flow across all layers, eliminating bottlenecks and aligning operations with Intermark’s strategic goals. By leveraging these connections, Intermark drives operational efficiency, improves customer satisfaction, and positions itself for long-term success in a dynamic market.

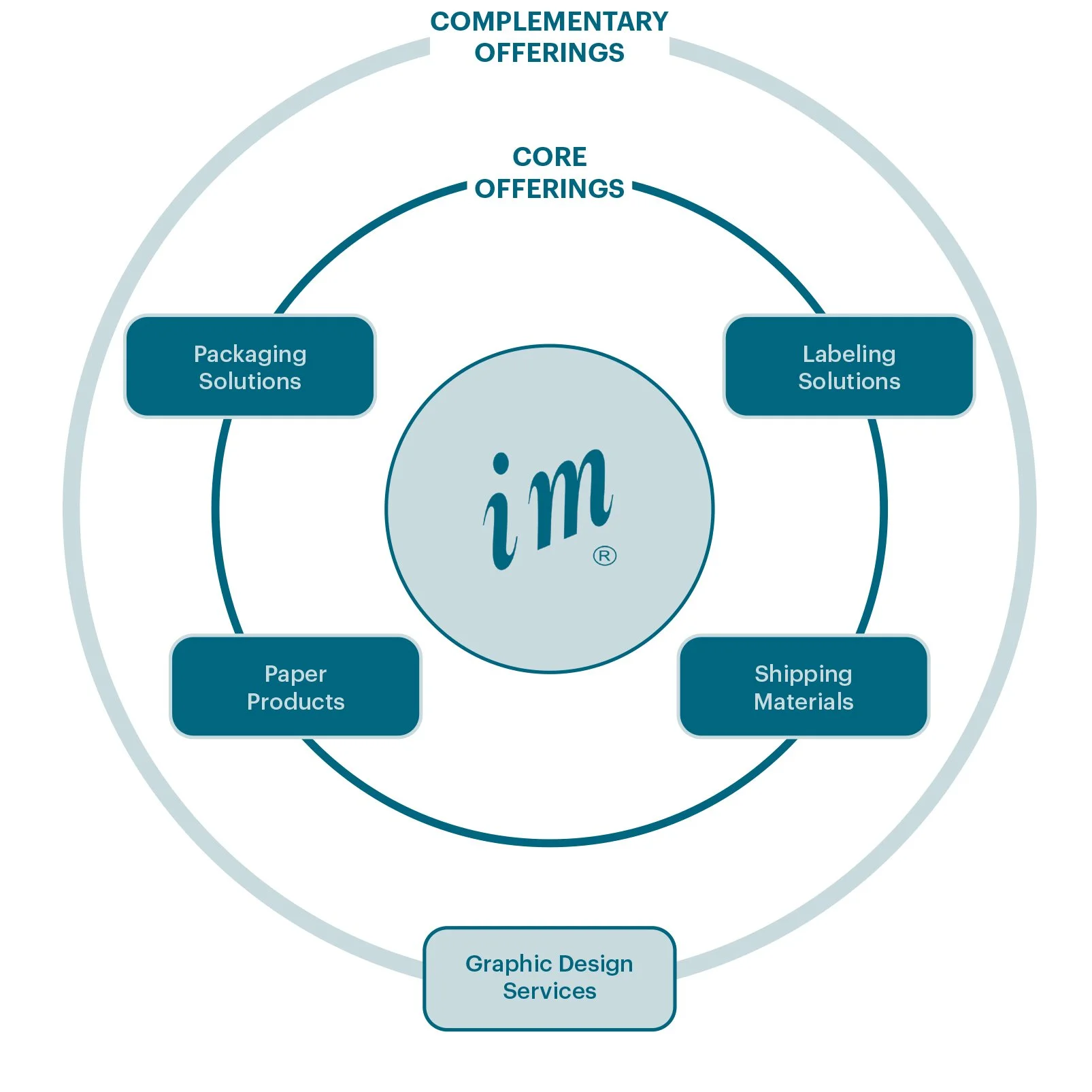

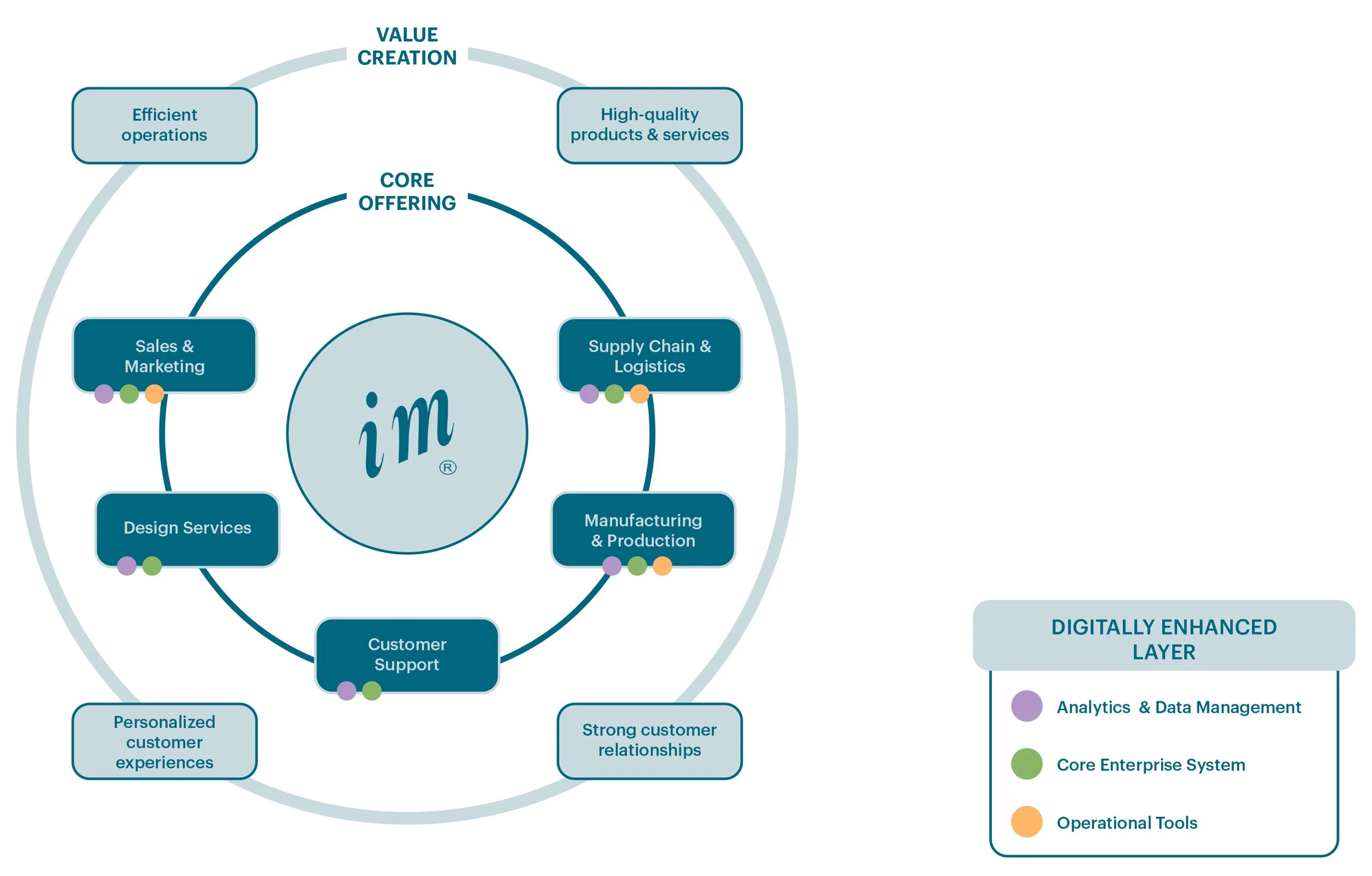

Digitally Enhanced Service Offering.

Intermark’s updated service offering incorporates a digitally enhanced layer that focuses on analytics, data management, core enterprise systems, and operational tools. This new layer is designed to optimise decision-making, enhance customer insights, and improve overall efficiency.

At the heart of this offering, core enterprise systems centralise workflows, inventory, and resource allocation, ensuring smooth coordination across all departments. Digital tools like project tracking and collaborative platforms streamline daily operations, reducing manual inefficiencies and supporting scalable growth.

This integrated approach strengthens Intermark’s value proposition by improving its operational capabilities and ensuring more customer-centric services. By leveraging data and technology, Intermark is better positioned to make informed decisions, respond quickly to market demands, and deliver superior customer experiences.

Expected Benefits.

Proposed Solution.

The centralised ERP system streamlines workflows by reducing manual tasks and facilitating real-time data sharing, which minimises delays and optimises resource allocation. This leads to operational efficiencies, with key impacts such as faster production cycles and smoother day-to-day operations.

—Operational Efficiencies.

Real-time dashboards and key performance indicators (KPIs) enable proactive management, while predictive maintenance helps prevent downtime and reduces repair costs. This results in faster, data-driven decisions and improved resource management.

—Enhanced Decision-Making.

ERP, CRM, and SCM systems facilitate seamless inter-department communication, enabling teams to collaborate efficiently through real-time data access. This fosters better coordination and smoother workflows across departments.

—Improved Collaboration.

The modular system offers scalability and flexibility, allowing for growth and the integration of new technologies. This ensures that the system remains future-ready and adaptable to industry changes.

—Scalability & Flexibility.

The enhanced customer experience is driven by real-time tracking, automated support, and product customisation, all of which contribute to a more seamless and personalised service. This approach leads to increased customer satisfaction and loyalty, fostering stronger long-term relationships with clients.

—Enhanced Customer-Experience.

Predictive maintenance and optimised inventory management help reduce operational costs. This leads to higher profitability by efficiently utilising resources.

—Cost Saving.

Proposed Solution.

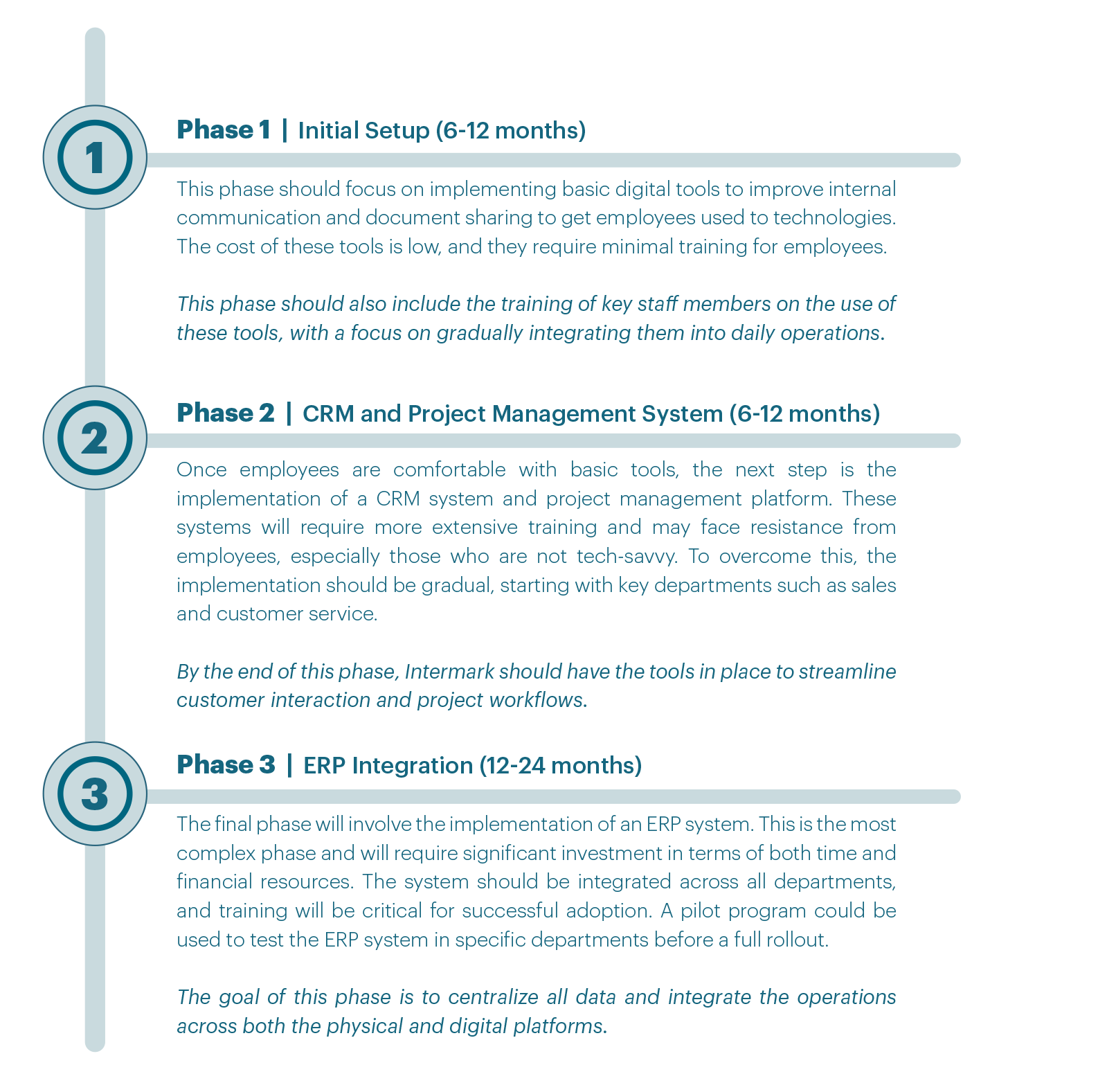

Implementation Plan.

Successful implementation requires allocating resources for employee training and ongoing support, ensuring smooth adoption of digital tools.

A dedicated team will oversee the process, address challenges, and monitor progress using clear KPIs.

Regular reviews will help track efficiency, reduce errors, and improve customer satisfaction, allowing adjustments as needed.

Resource Allocation & Staff Training.

Intermark’s Future Vision.

Intermark’s digital transformation goes beyond adopting technology—it represents a shift towards becoming a leader in customer-centric solutions and operational excellence.

By leveraging digital systems and data-driven strategies, the company is building a foundation for sustainable growth, adaptability, and long-term success.

Intermark’s Path.